MOX chemoresistive gas sensors based on MEMS microheater

Description

MEMS devices based on Bulk Micromachining technologies for the development of chemoresistive gas sensors. General Characteristics:

- The chemoresistive gas sensor consists of two main parts: a silicon microheater, to thermo-activate and read the signal of the sensing material; an advanced nanostructured semiconductor used as a gas sensing material.

- The gas sensing material works as a receptor, by interacting with the gases in the atmosphere, and as a transducer, by transducing the interaction with pollutant gases into a change of its electrical resistance.

- Si-Chip technology enables the microfabrication of ultrathin dielectric membrane for the sensing element, by allowing low power consumption of the device.

- Different kind of sensing materials and microheater layouts are developed in FBK, to determine the best combined solution.

Figures:

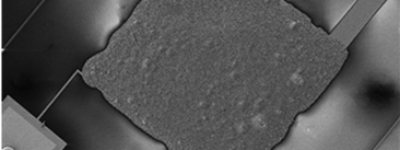

- Magnification of a chemoresistive gas sensor produced in FBK, by using a scanning electron microscope.

- Single chemoresistive gas sensors packaged on commercial TO supports.

- Calibration curve of a SnO2-based chemoresistive gas sensor response vs. CO concentrations, in presence of 30% of RH%

- Calibration curve of a ZnO-based chemoresistive gas sensor response vs. NO2 concentrations, in presence of 30% of RH%

Advantages & Applications

Development of single gas sensors or gas sensor arrays with low power consumption. The main advantage is related to the FBK control of the entire production line, starting from the microheater development to the sensing material synthesis and deposition. Such control allows the development of customized gas sensing platforms for specific applications. Further advantages of these devices are the high sensitivity, the fast response and the possibility to adopt dedicated algorithms to improve sensors selectivity. The chemoresistive gas sensors are used in different applications, such as outdoor/indoor air quality monitoring, precision farming and screening for the diagnosis of clinical diseases.

Specifications

- Chip size: 2.5 x 2.5 mm2 or 3 x 3 mm2

- Chip Thickness: 300 µm

- Gas sensing material area: 1 x 1 mm2

- Gases: NOx, Ozone, SO2, NH3, H2, CO, VOCs in general, such as, alcohols, HCOH, acetone, alkanes and so on

- Power consumption: 60-110 mW

- Response time: from 5 to hundreds seconds, depending on the packaging and on the gas analysed

- Recovery times: from 30 to hundreds seconds, depending on the packaging and on the gas analysed

- Limit of detection: from ppbs to ppms, depending on the gases analysed and RH% (e.g. CO 160 ppb and NO2 18 ppb, 30% of RH%)

Status

The FBK chemoresistive gas sensors are currently used alongside certified monitoring system of the Environmental Protection Agency of the Province of Trento.

The TRL level is between 7-8.

Contacts

-

Reference person: Pierluigi Bellutti

Tel. +39 0461 314 431, email: [email protected]

Research Unit MNF: mnf.fbk.eu

Research Center CMM: cmm.fbk.eu